EMT Bimetallic Material Characteristics

| Data | Part No | EMT-1 | EMT-2 | EMT-3 | EMT-4 | EMT-5 |

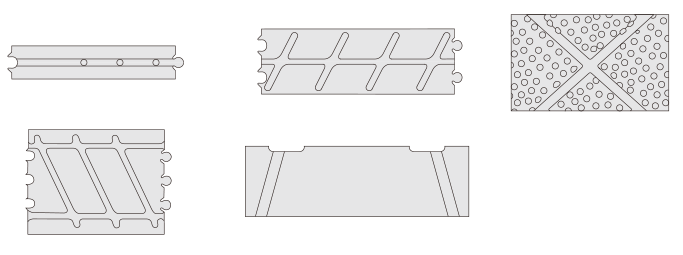

| EMT Structure |  |

|

|

|

|

|

| Steel+CuPb10Sn10 | Steel+CuPb24Sn4 | Steel+CuPb,0 | Steel+AISn20Cu | Steel+CuSn8Ni | ||

| Corresponding Code | SAE-792(SAE797). JIS-LBC3. |

SAE-799.JIS-LBC6. | SAE-48.JIS-KJ3 | SAE-783.JIS-AJL. | ||

| Clevite F100.GGB- SY.Daido L10. Federal Mogul HF -2F. Glyco 66. |

Daido L23. Glyco 68 |

Federal Mogul TR- 20. Glyco 74. |

||||

| Max Load Capacity P | 150/mm 2 | 130/mm 2 | 120/mm 2 | 100/mm 2 | 140/mm 2 | |

| Greaes Lubrication | ||||||

| Max Speed | 2.5m/s | 2.5m/s | ||||

| Maximum PVValue | 2.8N/mm2. m/s | 2.8N/mm2. m/s | 2.5N/mm2. m/s | |||

| Coefficient of friction | 0.05~0.15 | 0.06~0.16 | ||||

| (Oil)Lubrication | ||||||

| Max Speed | 10m/s | 10m/s | 15m/s | 25m/s | ||

| Maximum PVValue | 10N/mm2. m/s | 10N/mm2. m/s | 8N/mm2. m/s | 6N/mm2. m/s | ||

| Coefficient of friction | 0.05~0.12 | 0.05~0.15 | 0.06~0.17 | 0.06~0.17 | ||

| Max Working Temperature |

||||||

| Greaes Lubrication | 150°C | 150°C | 170°C | 150°C | ||

| Lubrication | 250°C | 250°C | 250°C | 250°C | 200°C | |

| Alloy Hardness | 60~100HB | 45~70HB | 30~45HB | 30~40HB | 70~120HB | |

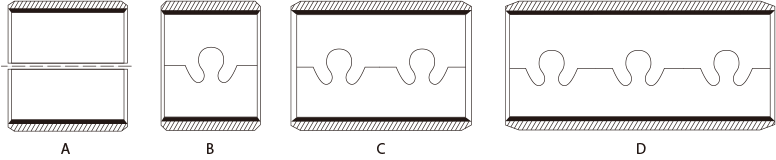

EMT Lubrication Design

EMT Split Gap Design

EMT Oil Hole Design

Oil Hole is necessary to design if EMT have lubricated sufficiently; the following oil hole design is recommended, which is also suitable for EMT series without special requirements.

| Bushing O.D. (D) | Φ14>D≤22 | Φ14>D≤22 | Φ14>D≤22 | Φ14>D≤22 | Φ14>D≤22 |

| Oil Hole Diameter (mm) | 3 | 4 | 5 | 6 | 7 |

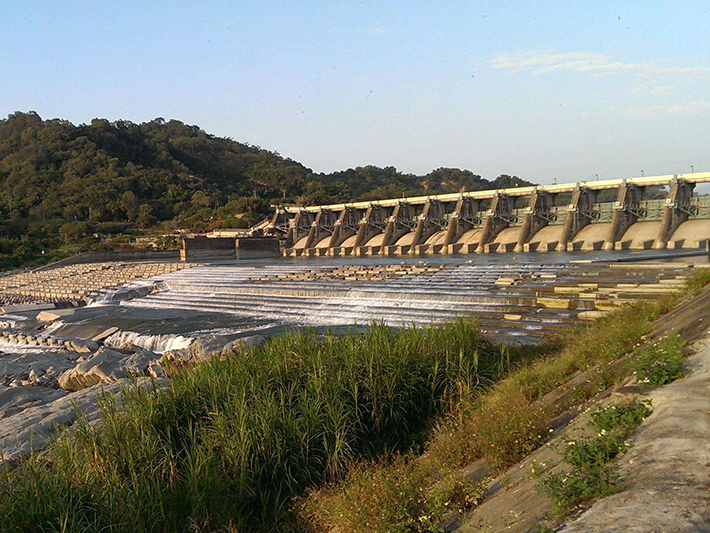

EMT Application

Oil Hole is necessary to design if EMT have lubricated sufficiently; the following oil hole design is recommended, which is also suitable for EMT series without special requirements.

| EMT-1 | Advantageous in high load carrying capacity, anti-impact, lower wear. Suitable for Mid-load capacity & Midhigher Sliding velocitie. Bushings for Gearbox, Rocker arm, King Pin, transmission etc. |

| EMT-2 | Higher fatige strength & load carrying capacity, goos running characteristics at higher sliding velocities. Suitable for Mid-load capacity & Mid-Sliding velocitie . Bushings for lubricating oil pumps . After surface specifical treatment, Bushings for Main bushes of high speed internal-combustion engine, Connecting Rod etc . |

| EMT-3 | Very Good sliding Characteristics, good anti-seizure property, special material, Punched oil grooves & oil pockets are not feasible. Bushings suitable for hydraulic Pump,automatic gearbox. After surface specifical treatme |

| EMT-4 | Mid fatige strength & load carrying capacity, very good fatige strength & load carrying capacity, very good sliding characteristics . Bushings for half-bearing of high speed, lower load internal-combushtion engine, aircomressor, refrigerator, hypoid gearbox, hydraulic pump, gearbox etc. |

| EMT-5 | The material composition of the product conform to the requirements of the Ro HS, under certain conditions can replace the EMT-1, has good load pressure & good wear resistance. The disadvantage is that it cannot be used without oil lubricant. But has great advantage in a well-lubricated situation. Suitable for heavy & medium load, Medium & high speed, as well as large impact loads. |