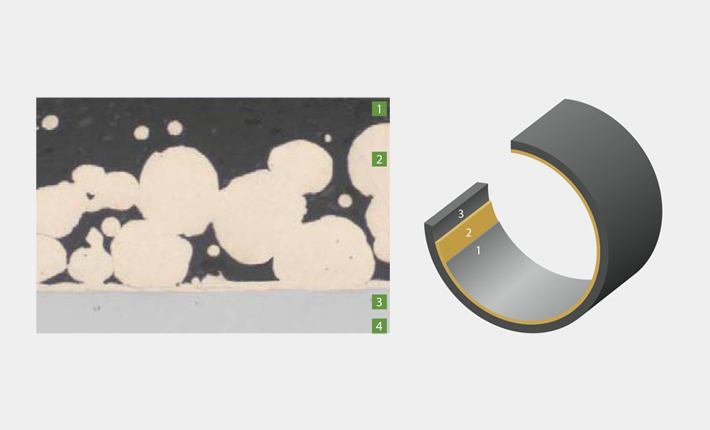

EU Structure

1. Self-lub. Layer PTFE Mixture 0.01-0.03mm. After rolling process completed, PTFE mixtures are filled in intersice of bronze layer. Under normal operation, Part of PTFE mixture on top layer will be removed and transferred on the mating surface, forms a physically lubricating film, which will reduced the firction coe. and protect the mating shaft.

2. Porous Bronze layer; The layer provides bonded strength of Self-Lub. Layer.

3. Steel Backing The layer provides load & thermal conductivity

4. Copper / Tin layer

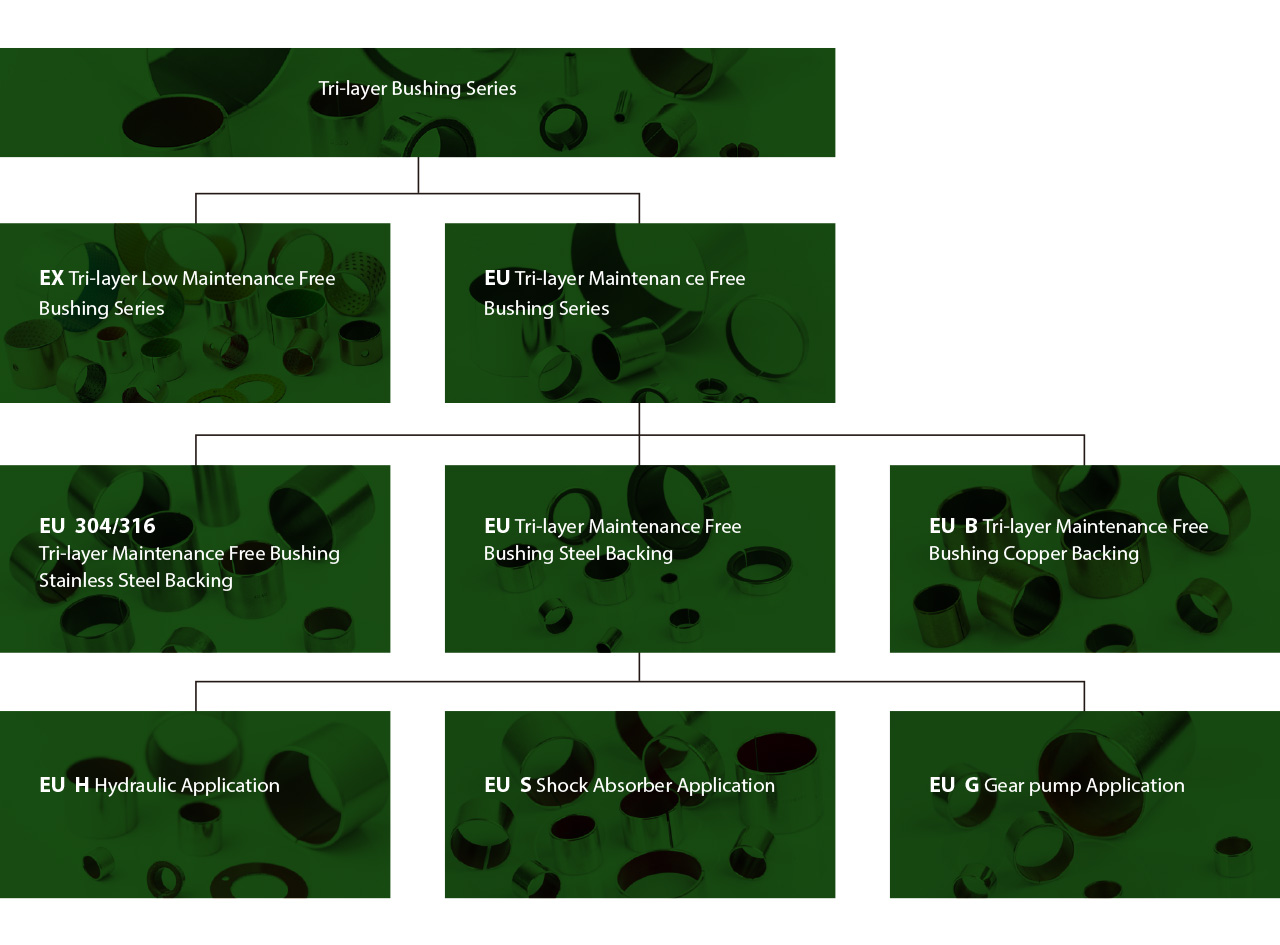

EU Material category

EU Material Characteristics

| Max. Load Capacity | ||

| Static Load | N/mm2 | 250 |

| Dynamic Load | N/mm2 | 140 |

| Max. Speed | ||

| Dry Running | m/s | 2.0 |

| Hydrodynamic Operation | m/s | >2 |

| Max. PV Value | ||

| Short-Term Operation | N/mm2 · m/s | 3.6 |

| Continuous Operation | N/mm2 · m/s | 1.8 |

| Coefficient of Friction | μ | 0.03~0.25 |

| Operation Temperature Range | ℃ | -195~280 |

| Thermal Conductivity | W(m · k-1) | 40 |

| Coefficient of Thermal Expansion | λST | 11 · 10K-1 |

EU Material Chemical Characteristic

| Type | Water | Sea Water |

Air | Alkaline Solutions |

Neutral Solutions |

Fuels& Lubricatis |

Strong Acid |

Weak Acid |

| EU | □ | ▲ | □ | □ | ★ | ★ | ▲ | ▲ |

| EU G | □ | ▲ | □ | □ | ★ | ★ | ▲ | ▲ |

| EU H | □ | ▲ | □ | □ | ★ | ★ | ▲ | ▲ |

| EU S | □ | ▲ | □ | □ | ★ | ★ | ▲ | ▲ |

| EU B | □ | □ | □ | □ | ★ | ★ | □ | □ |

| EU 304/316 | □ | □ | □ | □ | ★ | ★ | □ | □ |

| EX | □ | ▲ | □ | □ | ★ | ★ | ▲ | ▲ |

| ★Good □ Common ▲poor | ||||||||